ATAG has been producing award-winning heating products for more than 70 years, in which the development of innovative heating solutions and quality is central. And that is “just” in the Netherlands. With thorough craftsmanship and the down-to-earth sobriety, over 1,000,000 households worldwide now enjoy our sustainable heating products.

ATAG specializes in designing high-end boilers. At the heart of every ATAG boiler is our revolutionary iCon heat exchanger, which has unrivaled performance and efficiency levels. It’s made from high-grade stainless steel (as it has a longer lifespan than aluminum) and, uniquely, it maintains its original efficiency levels throughout its lifetime.

In order to maintain this, ATAG uses flue gas heat recovery. Normally small boilers are on-demand heating, so they use flue gasses to preheat water coming in, which in turn can improve efficiencies from 83% up to 98% when in use for things such as taking a shower.

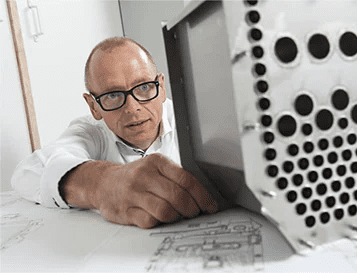

During a cost-saving project for their I-series boiler system, ATAG noticed a shift in acoustic performance after extensive acoustic testing. The changes had shifted the resonance frequency of the exhaust to match the natural frequency of the boiler. As such, the system was experiencing more vibration and generating more noise than it had before. To improve the acoustic performance without project delay, the problem needed to be resolved as soon as possible.

In order to eliminate the noise, they needed to dampen the harmonic. This was done by tackling the design of the exhaust piping. While previous work of this genre was done via prototyping, this workflow was deemed too slow for such a time-sensitive matter. Which could have resulted in the cancellation of the cost-saving project.

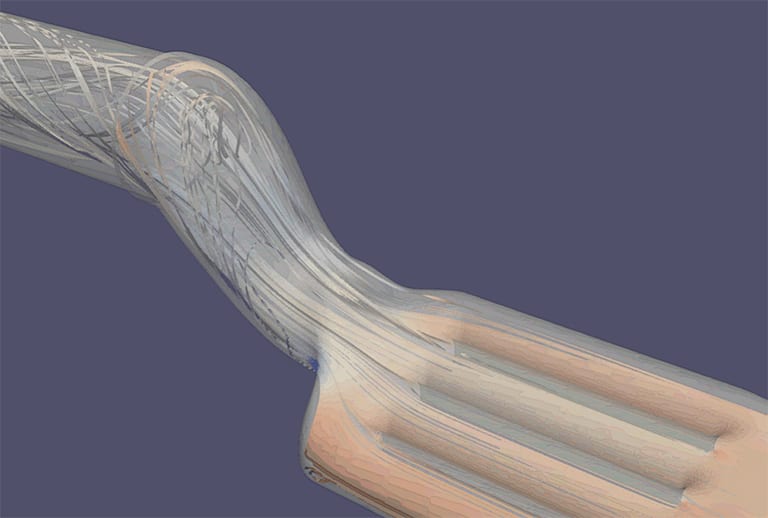

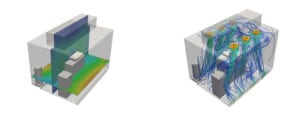

Instead, ATAG turned to CFD and, more specifically, SimScale. Both finite element analysis (FEA) and computational fluid dynamics (CFD) simulations were performed. The FEA looked at the natural frequency of the exhaust piping, and how new shapes and designs could shift that frequency away from the main boilers. On the other hand, the CFD calculations identified areas of high turbulence and vortex shedding in order to nip the problem in the bud.

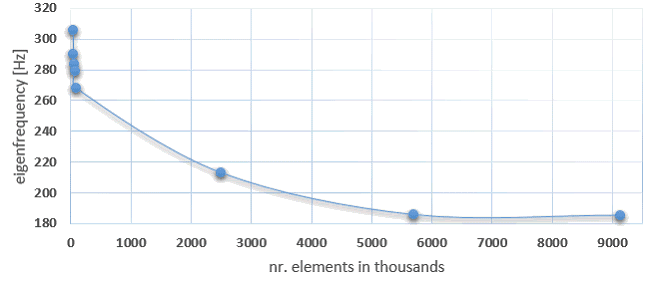

ATAG was able to leverage the cloud, running over ten simulations in parallel. This allowed them to perform a mesh independence convergence study, building confidence in their results.

“SimScale’s parallelization capability saves time. This precious time was used to turn our cost-reduction project into a performance upgrade for our customers at the reduced cost.”

Tirdad Ahmadpour

Engineer

After the design modifications were made, it was found that the eigenfrequencies of the exhaust piping had been shifted away from the critical 120 Hz zone that created the issue. ATAG did not stop there though, and moved onto their third design iteration of the part, with a plan to still go further.

Due to the fact they were able to save time through online simulation compared to physical prototyping, they have found the time to start optimizing the piece not only for noise reduction but also for pressure drop. The initial proposed solution to the problem solved the noise issue, but the extra reinforcements added to the internals to stiffen the part was causing eddies in the flow which increased the pressure losses. In the next phase of the project, by further design changes informed through their CFD studies, ATAG reduced the pressure drop through the exhaust piping by 70%. As a final step, ATAG ran prototypes of their final design and found a great fit between the predicted performance and actual system.

ATAG expects to expand this work to other parts of their boilers, and look into further design improvements. As each prototype of the exhaust piping costs around 800 EUR and the final tooling over 50,000 EUR, simulation through the cloud quickly pays for itself.

With the cost and time savings the team experienced using SimScale, they are also considering taking a deeper look at the vortex shedding mechanism observed earlier with a full transient large eddy simulation. They plan to use SimScale to determine the possibility of resolving this design conundrum by adding a “golf ball” topology to some of the piping, and investigating what sort of changes they can make to the system that is possible by only modifying the current tooling rather than producing a new one from scratch.

Here at SimScale, we look forward to continued collaboration, and what the team at ATAG will accomplish in the near future!

Sign up for SimScale

and start simulating now